ASSEMBLY

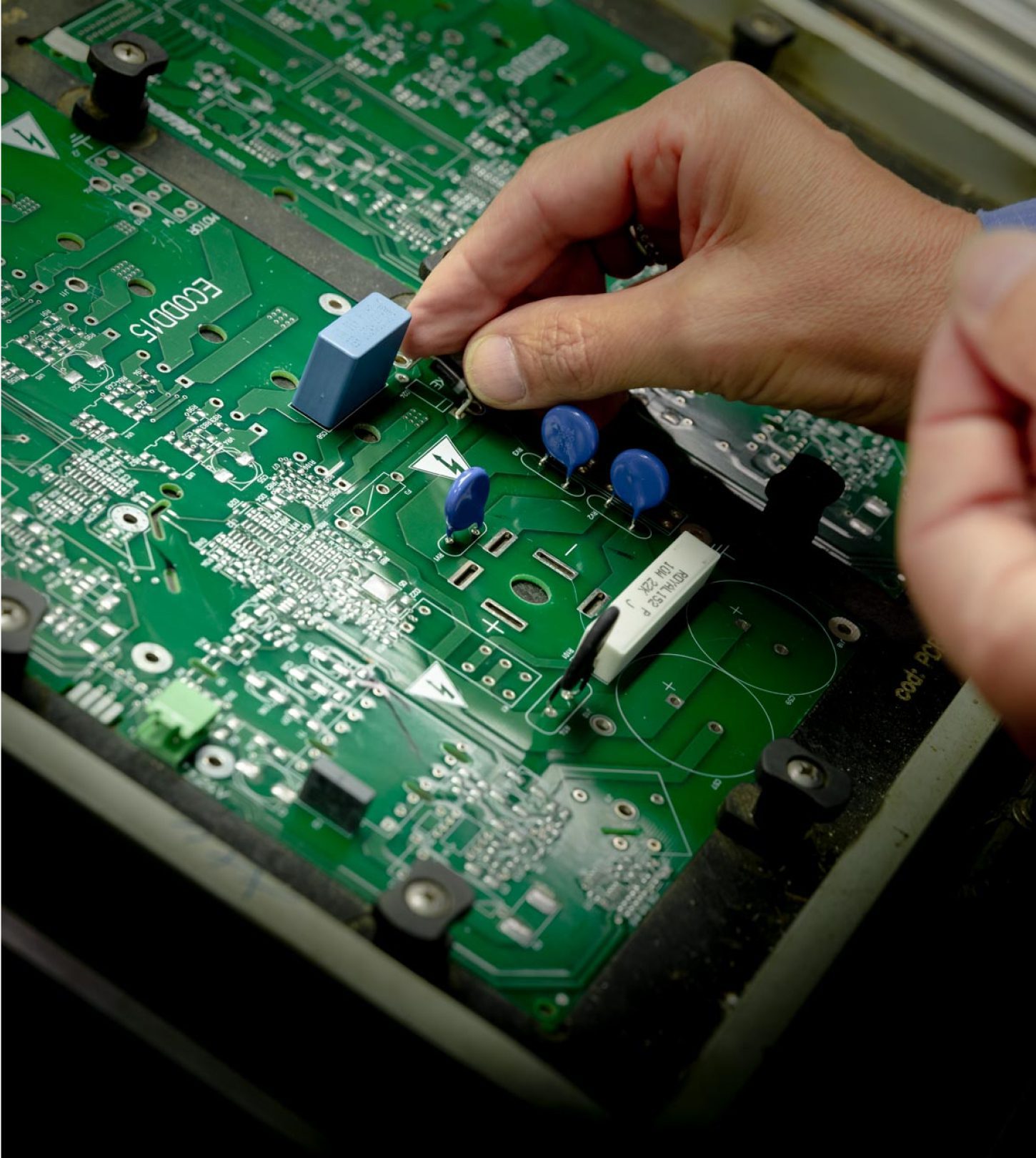

SMT AND THT BOARD ASSEMBLY

The electronic board assembly activities take place based on highly developed RoHS or Leaded processes, based on reliable next generation automated machinery featuring highly repeatable processes.

The SMT (Surface Mount Technology) process is totally automated both during assembly and control stages. This means that in addition to assembling odd shape components we can also assemble extremely small components like the 0201, thus reducing product bulk.

Controlled assembly stage

STATE-OF-THE-ART TECHNOLOGY

The fundamental stage of the SMT assembly process are entirely 100% controlled by automated systems:

- 3D Solder Paste Inspection: volume check of solder paste deposits;

- Automatic Optical Inspection: verification of the size of soldering points and the positioning of components compliant with IPC-A-610 specifications.

The THT (Through Hole Technology) process entails the completion of the electronic boards with PTH (Pin Through Hole) components followed by automated soldering. Even for this stage the process is assessed based on the product’s characteristics, with the use of state-of-the-art machinery for both wave soldering and for selective spot by spot soldering.

The checks are carried out using suitable professional enlargers based on the product’s characteristics and x ray machinery. Critical component reworking as required by BGA components is carried out on semi-automated ZEVAC rework stations.